3D engineering

3D Engineering at Pharmatec

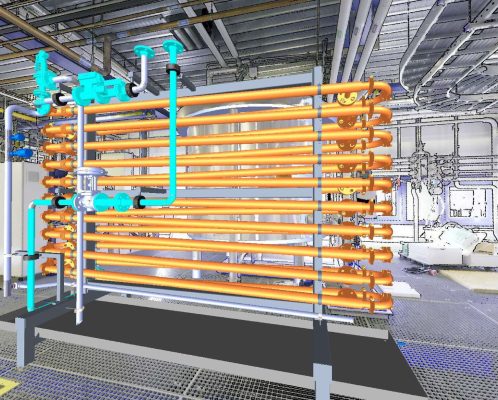

At Pharmatec, process plants are designed with extreme care, focusing on specific requirements and capacity demands. This approach is essential to meet the highest standards in the industry. From the beginning, during the phase of feasibility studies, to final commissioning, we guarantee thorough integration of all required components.

Cooperation with various partners in process automation highlights the versatility of the approach we take. Through advanced software and technological solutions, not only the capacity of the plant is calculated, but also the design of the utilities is carefully optimized.

Our working method

Pharmatec distinguishes itself by meticulously directing project management, where each phase of the process is strictly supervised and delineated. Real-time communication with the client and other stakeholders, as well as close monitoring of agreed budgets, schedules and quality goals, are integral aspects our practices.

This commitment to detail and quality translates into durable, efficient process plants that meet the highest standards in a variety of industries, including pharmaceutical, petrochemical and food processing. We remain at the forefront of designing process plants that not only meet today's requirements, but are ready for the future.

Customized solutions

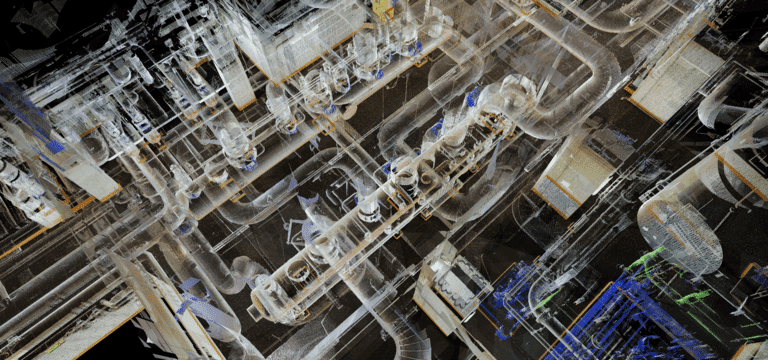

Pharmatec demonstrates its versatility by using advanced technologies such as 3D laser scanning and modeling with point clouds for your process plants. This innovative approach enables us to create accurate and detailed virtual models. By integrating 3D technologies, this not only improves the design process, but also optimizes the efficiency of the entire project, allowing clients to benefit from advanced visualization and planning. With 3D laser scanning and point cloud modeling, Pharmatec delivers customized solutions that meet the highest industry standards.